The Mystery of Digital Twins

What are Digital Twins?

A digital twin can be defined as the digital replica of a physical product, process or services. The digital twins act as a bridge between the physical and digital worlds by using sensors for collecting data about a physical item in real-time. This data can be used for creating digital duplicates of an item, giving the allowance of understanding, analyzing, manipulating, and optimizing. The generated data helps the businesses in better analysis and predicting the problems in advance or even give early warnings. This also helps the businesses to develop new opportunities and also plan better products for the future at lower costs by the use of simulations. All of these outcomes of digital twins would help in delivering a better customer experience for the businesses. This concept of digital twin technology is based on three pillars- the first one being that a physical object or device exists in real space, the second is that a virtual product exists in the digital world and lastly, there exists a bridge which connects the physical and virtual object which helps in sending and receiving data as well as information between them.

Working of Digital Twin

The physical objects or the systems are incorporated with smart components that are used for accumulating the real-time data. These components are mostly connected to cloud-based systems that monitor the accumulated data and the final data that is obtained is used for production.

In order to create a digital twin of any physical object, the data is collected and synthesized from diverse sources such as- physical data, manufacturing, operational data and insights from analytics software. All the collected information is then integrated into a physics-based virtual model and when analytics is applied to these models, relevant insights regarding the object can be gained. This consistent data flow helps in getting the best possible analysis and insights regarding the object which can be used for optimizing the business outcomes. This way, the digital twin is going to act as a live model of a physical object.

Types of Digital Twin

1. Product Digital Twins

The product Digital Twin is used for providing a virtual-physical connection which can be used for analyzing the performance of a product under different conditions and make adjustments in the virtual world to ensure that the physical product will perform exactly as planned. Product digital twins help in navigating the complexity of systems in order to make the best possible decisions. The need for multiple prototypes, reduced total development time, improved quality of product is directly eliminated. Faster iterations in response to customer feedbacks are also enabled because of the Digital Twins

2. Production Digital Twins

A production twin helps in validating the working of a manufacturing process on the floor before actually going into production. By simulation of a process using the Digital Twin and then analyzing why certain things happen using the digital thread, the companies are able to create a production methodology in a more efficient manner under a set of conditions. The production process can be optimized by creating digital twins of all the manufacturing equipment. By using data from product and production digital twins, the businesses are now able to prevent the costly downtime to equipment and predict when the preventative maintenance is needed. The constant stream of accurate information is used for enabling the manufacturing operations that are fast, efficient, and reliable

3. Performance Digital Twins

The smart products and plants generate large amounts of data in terms of their utilization and effectiveness. The performance Digital Twin can capture this data from products and plants in operation and then analyze it to provide actionable insights on informed decision making.

By leveraging the performance Digital Twin, companies are able to-

- Create new business opportunities

- Gain insights for improving the virtual models

- Capture, aggregate, and analyze the operational data

- Improve the efficiency of product and production system

Applications of Digital Twins

The concept of Digital Twin is nearly the next big thing for various business verticals, which can help in accurately predicting the current state and future of physical assets by analyzing the digital counterparts of the real-world entities. With the implementation of Digital Twins, organizations tend to gain better insights related to product performance, improvement in customer services and making better operational as well as strategic decisions that are based on these insights.

Some major industrial applications of Digital Twins could include the following-

1. Manufacturing

Digital Twins can create a significant impact on the way products are being designed, manufactured, and maintained. It has made manufacturing more efficient and optimized while reducing the throughput time

2. Automobile

Digital Twins are used for creating the virtual models of connected vehicle. It captures the behavioural and operational data of the vehicle and helps in analysing the overall performance of vehicle as well as their connected features. It could also help in delivering a truly personalized service to the customers

3. Retail

Implementation of Digital Twins plays a key role in augmenting the retail customer experience. This can be done by making virtual twins for customers and modelling fashions for them on it. The Digital Twins could also help in better instore planning, security implementations and management of energy in an optimized method

4. Healthcare

Digital Twins combined with IoT play a key role in the healthcare sector, which can range from saving the costs to monitoring patients, preventative maintenance and even providing personalized health care

5. Smart Cities

The smart city planning and implementing it with Digital Twins and IoT data can help in enhancing economic development, efficient management of resources and thus increasing the overall quality of a citizen’s life. The Digital Twin model can help the city planner and policy maker involved in smart city planning by gaining insights from the different sensor networks and intelligent systems

6. Industrial IoT

The industrial firms along with digital twin implementation are now able to monitor, track, and control the industrial systems by digital means. Besides, the operational data, digital twins can are used for capturing environmental data such as location, configurations etc. helping in predicting the future operations

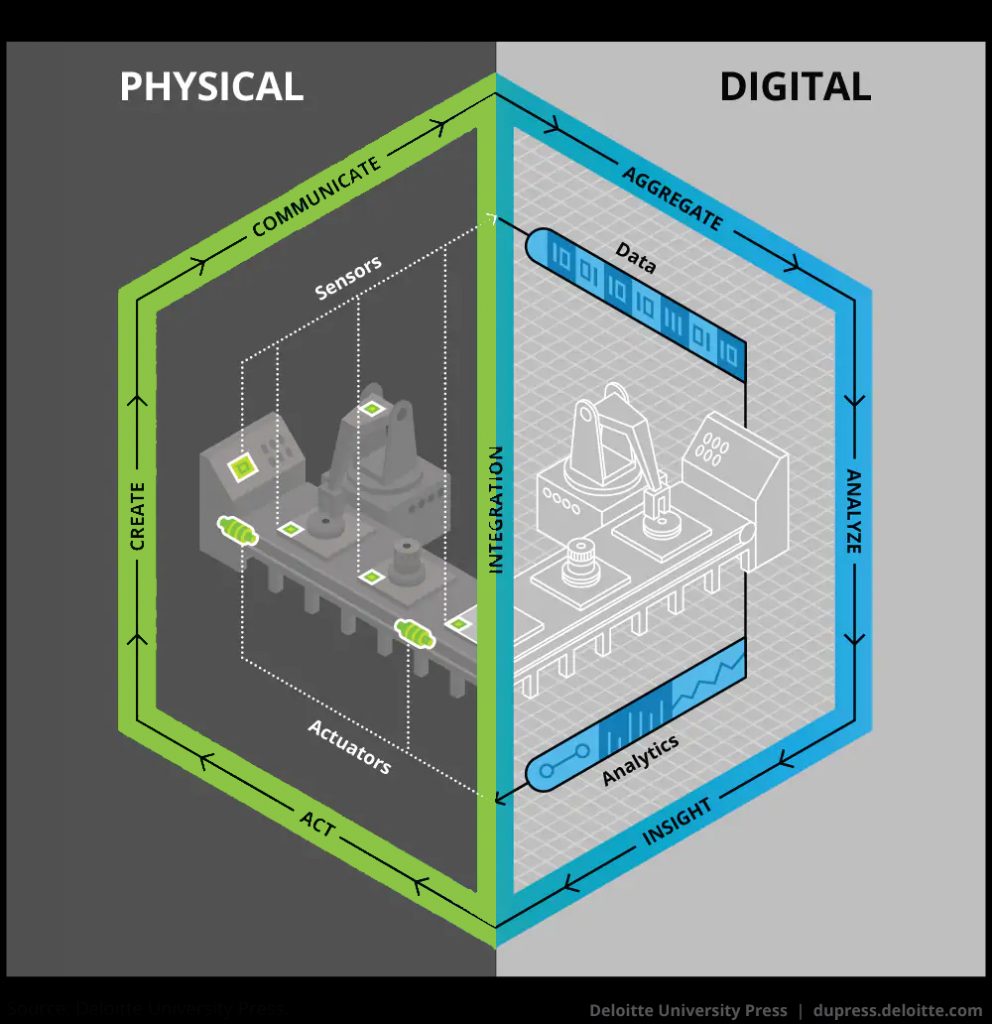

Manufacturing Process Digital Twin Model

There are five enabling components in the Digital Twin Processing Model, which includes- sensors and actuators from the physical world, integration, data, analytics, and the regularly updated twin application.

1. Sensors

Sensors are distributed throughout the manufacturing process to create signals which enable the twin to capture the operational and environmental data which pertains to the physical process in the real world

2. Data

The real-world operational and environmental data from sensors are aggregated and combined with the data obtained from the enterprise. The obtained data may also contain other data as well such as- connections to external data feeds, and customer complaint logs

3. Integration

Sensors communicate their data to the digital world through the means of an integration technology between the physical world and the digital world, and vice-versa

4. Analytics

The analytics techniques are used for analyzing the data by the means of algorithmic solutions and visualization routines used by the Digital Twins for producing insights

5. Digital Twins

The objective behind Digital Twin is to identify the intolerable deviations from the optimal conditions along any dimension. Such deviations are the case of business optimization or the twin has faced a logical error

6. Actuators

Is there an action that has to be warranted in the real world where the digital twin produces the action by actuators, subjected to human interventions which trigger the physical processes

Benefits of Digital Twins

The introduction of Digital Twin not helps in manufacturing high-quality products and services with ease, but also it saves a lot of money which is spent on production. Creating virtual templates replaces the entire construction of manufacturing. Thus, all the possible fixtures related to the most sophisticated problems having a limited budget and dynamism can be tested.

Another important advantage that the Digital Twins offer is that- once they are created, it lasts for the entire lifetime of the products. The installed IoT sensors in the physical machine constantly send and receive the information of its Digital Twin, thus Digital Twin remains up to date with the working condition of the IoT devices. This information is then used for improving the quality of the product of the same nature. The sensors also allow the data scientists to gain information about the potential loopholes and help in controlling the cost of expensive repairs and fasten the maintenance procedures also.

Digital Twins also helps the businesses to launch their products and services to the market at faster rates than the competitors. The integration of technologies like Digital Twin Applications, Data Science, AI, and IoT makes these process smooth and accurate.

Future of Digital Twins

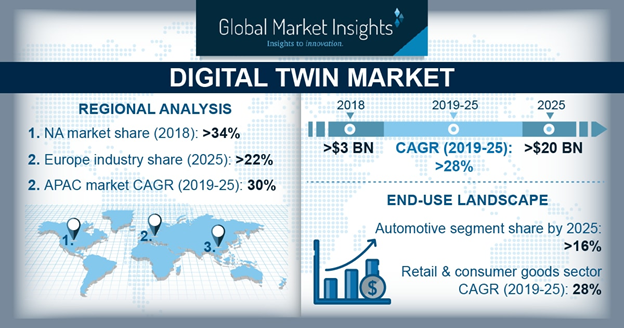

The global market of Digital Twins market was valued at $2.26 billion in the year 2017 and is expected to grow at a CAGR of 38.2% from 2018 to 2025. The key drivers which influence the growth of this industry include- the increasing adoption of IoT and IIoT, as well as the rapid growth in digitization in industry verticals such as- manufacturing, automotive, and healthcare. The ever-rising adoption of Internet of Things is empowered by 3D simulation, deep learning, Artificial Intelligence, and Big Data analytics is going to help in the cost-effective implementation of digital twins in aerospace & defense, healthcare, retail, and consumer goods sector.

Also, there is an ever-rising demand to reduce the asset downtime, optimize process time, and, improve the operational efficiency is blooming the growth of this market. The support from the government initiatives related to smart cities construction and energy-efficient smart buildings will be the key drivers of this market during the forecasted period.

In terms of industries, the healthcare sector is expected to have a dominant market share in the digital twin market. The digital twin in this industry offers real-time monitoring & analytics with machine learning to help in streamline operations and processes in hospitals, leading to improved customer experience. It is expected that the manufacturing sector will have a market share of 25% in this market by 2025. This growth is attributed to the robust rose in the manufacturing industry post Industry 4.0 as well as the emergence of automation systems in the manufacturing sector for rapidly increasing production capabilities.

The Digital Twins form the bridge between the physical and digital worlds. They can generate value to businesses by offering lesser maintenance costs, newer revenue streams, and better management of the assets. With the improvement in technology and virtualization taking over the markets, businesses are now going to deploy the Digital Twins with lesser capital investments and gaining greater ROIs in a short period of time

- Considering Data Centers in India to Overcome Economic Conditions - May 10, 2022

- Determining Why Your Organization Needs Web Application Security - February 11, 2022

- How Does a Business Benefit with Managed Services - January 21, 2022